Kawasaki Heavy Industries Opens Orders for Commercial Hydrogen-Blended Gas Engine

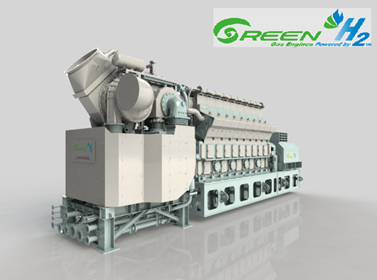

Kawasaki Heavy Industries has started taking commercial orders for what it says is the world’s first gas engine designed to operate on a hydrogen and natural gas blend, a development that signals growing momentum in the push to reduce carbon emissions from power generation. The company began accepting orders in late September 2025 after completing nearly a year of large-scale verification testing at its Kobe facility.

The newly introduced KG series engine can run on a fuel mix that includes up to 30 percent hydrogen by volume, combined with natural gas. This blend level is significant because it allows energy producers to incorporate hydrogen without overhauling their existing fuel infrastructure. Power plants can continue using current pipelines and storage systems, helping operators avoid major capital investments while still taking initial steps toward cleaner energy.

Despite the technological readiness of the engine, hydrogen availability remains a key constraint. Japan relies heavily on imported energy, and commercial hydrogen supply networks are still in early stages of development. As a result, while utilities can technically deploy the engine immediately, securing a consistent hydrogen supply may prove challenging in the short term.

Upgrading Existing Engines Instead of Replacing Them

A central feature of the KG platform is its compatibility with earlier models. Kawasaki has spent more than a decade refining this engine line, and previous versions have recorded over 240 orders globally since their introduction in 2011. Many of these existing engines can be upgraded to support hydrogen co-firing.

This retrofit pathway offers a practical alternative to replacing entire power systems. Operators of older natural gas plants can modify their current equipment to accommodate hydrogen blends, extending the lifespan of their assets while gradually lowering emissions. The approach reduces the financial burden associated with building new facilities from scratch and supports a phased transition to cleaner fuels.

The company’s extended testing program, which ran from October 2024 to September 2025, focused on real-world operating conditions. Engineers assessed how the engines would integrate with hydrogen delivery systems and evaluated long-term maintenance requirements. Safety procedures were also a major focus, particularly given hydrogen’s distinct physical properties.

Engineering Solutions for Hydrogen Safety

Hydrogen behaves differently from traditional fuels like natural gas, creating unique engineering challenges. Its molecules are extremely small, making leaks harder to contain. The gas can also weaken certain metals over time and ignite more easily under a wider range of conditions.

To address these issues, the KG series incorporates multiple layers of safety technology. Hydrogen sensors are installed throughout the fuel system to quickly detect any leaks. In addition, nitrogen purge mechanisms are used to clear fuel lines during startup, shutdown, or emergency situations. These systems are designed to minimize risk and support safe, long-term operation in industrial settings.

Hydrogen Progress Extends to Maritime Applications

Kawasaki’s advances in stationary power coincide with parallel developments in hydrogen-powered marine engines. In October 2025, the company worked with Yanmar and Japan Engine Corporation to complete land-based operational tests of several hydrogen-fueled marine engines.

The trials used a newly developed liquefied hydrogen supply system and included different classes of engines. Medium-speed four-stroke engines demonstrated stable performance while running on hydrogen. At the same time, Japan Engine Corporation continued development of a large low-speed two-stroke hydrogen engine intended for use in major commercial ships, with its first operational run targeted for 2026.

These marine engines are built with dual-fuel capability, allowing ships to switch between hydrogen and diesel. This flexibility is considered essential during the early years of hydrogen adoption, as refueling infrastructure will vary widely between ports. Vessels that can operate on both fuels can reduce emissions where hydrogen is available while maintaining operational reliability on conventional fuel when necessary.

Public Investment Supports Hydrogen Innovation

The marine hydrogen project receives backing from Japan’s Green Innovation Fund, managed by the New Energy and Industrial Technology Development Organization. The Japanese government has committed roughly 2 trillion yen to this initiative as part of its long-term plan to achieve carbon neutrality by 2050.

Both the stationary and marine hydrogen programs depend on infrastructure that is still being built. To support future demand, Kawasaki is investing not only in engines but also in hydrogen production, storage, and transportation systems.

Large Hydrogen Import Terminal Under Development

In November 2025, Kawasaki partnered with Japan Suiso Energy to begin construction on the Kawasaki LH2 Terminal in Ogishima. The project is positioned as Japan’s first large-scale liquid hydrogen import facility and is expected to start operations around 2030.

The terminal will include a 50,000-cubic-meter storage tank for liquid hydrogen, which the companies describe as the largest planned facility of its type. It will also feature port handling equipment and truck loading systems, enabling the site to function as a central hub for hydrogen imports and distribution.

Because Japan has limited domestic renewable energy resources, imported hydrogen is expected to play a major role in the country’s long-term energy mix. As part of this strategy, the partners are also designing a 40,000-cubic-meter liquid hydrogen carrier ship. This vessel represents a significant expansion beyond the earlier demonstration ship, the Suiso Frontier, which carried out the first pilot hydrogen shipment from Australia to Japan in 2022.

Comments are closed.